- sales@battfix.com

- Add: No. 188, Zhaogang Road, Xiang'an District, Xiamen City, Fujian Province, China

- 86-18650326308

New energy vehicle maintenance background

In recent years, the number of new energy vehicles has continued to increase. As of the end of June 2022, the number of new energy vehicles in my country has exceeded 10 million! In the future, the market will stimulate a large number of after-sales maintenance needs. More and more existing new energy passenger cars have exceeded the warranty period, bringing many battery problems...causing a reduction in mileage and even causing a breakdown halfway! More than 90% of them are caused by unbalanced cells!

In response to various battery pack failures and unbalanced cell voltage problems of new energy passenger cars, BattFix launched a one-stop solution for testing and maintenance of lithium batteries for new energy passenger cars. Extend battery life, reduce the number of scrapped power batteries, and help the new energy industry achieve carbon peak and carbon neutrality.

As a professional lithium battery operation and maintenance instrument supplier, BattFix provides batch operation and maintenance testing equipment for well-known new energy vehicle companies such as Xiaopeng, Weilai, BYD, and Leapmotor, and launches a complete testing and maintenance solution for after-sales maintenance of new energy passenger cars.

01 Efficient Cell Equalization — LIFG Series Lithium Battery Equalization Tester

Multi-channel high-power equalizer, intelligent charge and discharge equalization, effectively solve the problem of reduced mileage caused by excessive battery loss or improper maintenance of new energy passenger vehicles.

Solve the problem of cruising range loss caused by excessive battery drains and improper maintenance.

The LIFG Series Lithium Battery Equalization Tester is designed to efficiently address cell voltage imbalances. This intelligent and high-performance device is ideal for simulating voltage differences between cells to replicate real-world conditions, making it perfect for R&D experiments. Compatible with various lithium battery types, it is an essential tool for battery manufacturers, EV manufacturers, and service providers, ensuring precise and reliable equalization for improved battery performance and longevity.

02 Battery Testing and Maintenance — FGCD Series Discharge-Charge Unit

Solve the problem that the EVs cannot be fully charged or the voltage is insufficient.

Covering the application scenarios of 0-1000V voltage range, effectively solving the problem of new energy passenger vehicles unable to be fully charged or insufficient voltage.

The FGCD Series utilizes advanced discharge and charge technology, offering various built-in test modes. It is designed for discharging, charging, and performing cycle charge/discharge tests on different lithium battery packs.

03 Battery Pack Leak Detection — FQ Series Airtightness Tester

For solving the airtightness performance verification test after unpacking repair.

High-precision non-destructive air tightness detection equipment, solves the air tightness performance verification test after unpacking and maintenance.

FQ-80L Battery Leakage Tester is a state-of-the-art, high-precision nondestructive testing device developed by FUGUANG. Utilizing compressed air, it applies controlled pressure to the inner cavity or surface of a battery pack and uses sensitive sensors to detect pressure changes, identifying any leakage. This method ensures quick, accurate, and pollution-free testing, greatly improving testing efficiency and product quality for customers in the new energy industry.

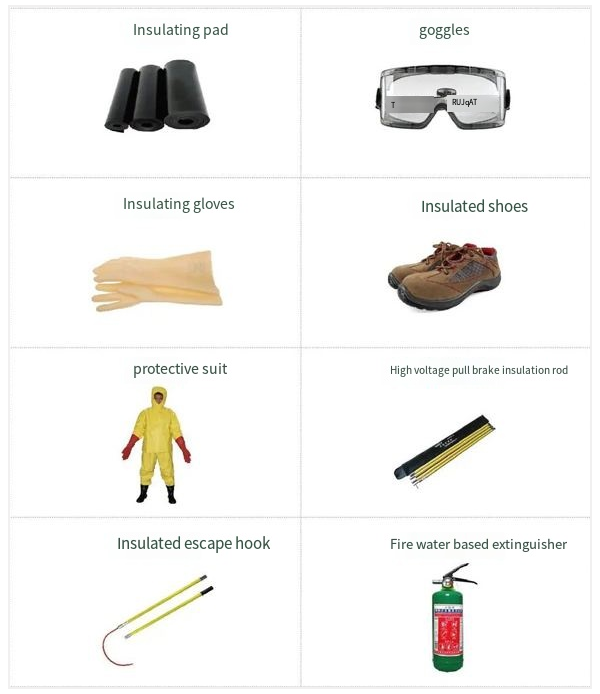

04 Safety protection

Insulation protection equipment + insulation tools, for the high-voltage risks of faulty vehicles and the high-voltage power battery packs of these vehicles.

Contact: Mr.Wen

Phone: +8618650326308

E-mail: sales@battfix.com

Whatsapp:+86 18650326308

Add: No. 188, Zhaogang Road, Xiang'an District, Xiamen City, Fujian Province, China

We chat